How luthiers voice an acoustic guitar top

The dark art of ‘voicing’ a guitar top is part science, part art, but ultimately about adding and subtracting in all the right places

All the latest guitar news, interviews, lessons, reviews, deals and more, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

In this age of algorithms and automation it seems it seems it’s become increasingly important to draw boundaries around different disciplines, often distinguishing people we know as ‘arty’ or ‘academic’ types, and jobs being designated to specific ‘sectors’.

One of the things I love most about guitar making is the way it sits right in the middle of that beautiful, multidisciplinary space that encompasses art, science, music and even (at times) psychology.

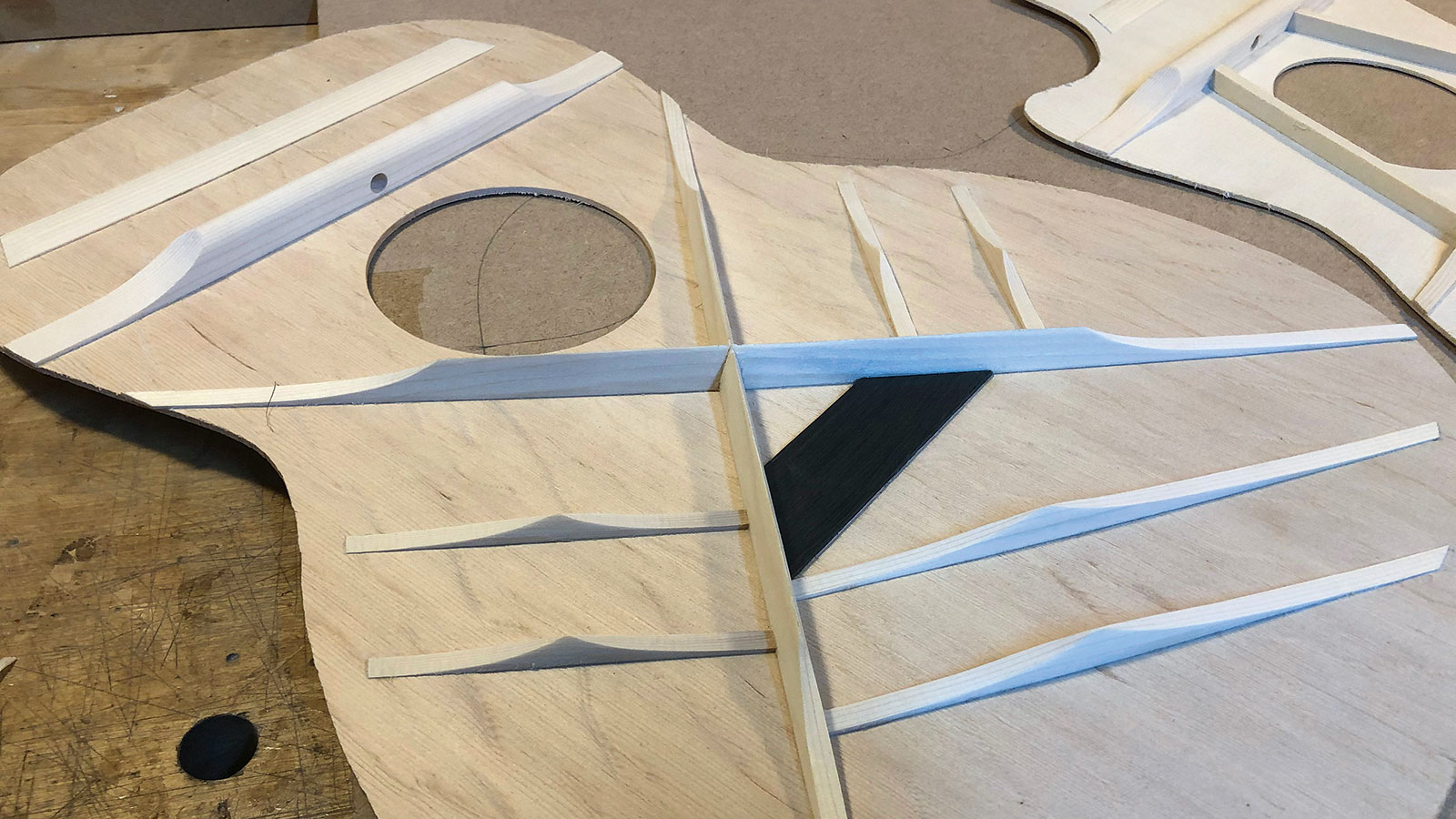

For the uninitiated, voicing a guitar top is the process of carving away at the oversized struts of softwood glued to the underside

This week I return to the workbench after some time away and I’m reminded of this because I’m straight in the deep-end, faced with voicing the tops of the two acoustic guitars I am currently building.

For the uninitiated, voicing a guitar top is the process of carving away at the oversized struts of softwood glued to the underside until we’re left with a structure that perfectly balances the job of strengthening the wood against the pull of the strings, while also giving it enough flexibility to project the desired tone.

Essentially, it’s all about adding just the right amount in just the right places, and removing any wood in places where it isn’t needed.

An acoustic guitar of the finest quality will last a lifetime, but it is also built to be as delicate as possible so that its ability to vibrate and amplify the acoustic energy released in the strings is maximized.

If overbuilt, the guitar will work, but its tone is dampened. If underbuilt, the tone may be awash with overtones but lack focus, and at worst become unplayable or even fall apart within a short time.

All the latest guitar news, interviews, lessons, reviews, deals and more, direct to your inbox!

Of course, the trouble with voicing a top is you have to do it without a finished guitar in front of you. So how does one predict whether the material you are removing is going to make things sound better or worse?

If overbuilt, the guitar will work, but its tone is dampened. If underbuilt, the tone may be awash with overtones but lack focus, and at worst become unplayable

Some time ago I watched a long-lost video of a Spanish guitar builder demonstrating his voicing process. He essentially rang out chords on the guitar in his lap, and then running his fingers along the top was able to identify areas that noticeably altered the tone, like a sort of EQ.

He would then add or remove material in those areas by working through the soundhole. It was the most convincing display of properly voicing a guitar top I’ve ever seen – but not an easy skill to learn by any stretch.

Some luthiers use special ‘jigs’ to measure how much their tops will deflect given a fixed load and they will carve away at the struts until the desired deflection is achieved. In the unpredictable world that is lutherie, I find this scientific approach rather appealing. However, it’s quite a general way of working and doesn’t really account for the necessity to have more strength in some areas than others in order to optimize the tone.

Formula for success

To build guitars in a purely technical way is to completely overlook the excitement of playing a guitar that sounds, looks and feels truly unique

Ultimately, there are probably as many approaches to voicing a guitar as there are guitar makers in the world. My own method involves routing out the brace blanks using templates so that the starting point for the bracing of every guitar I build is the same.

It is only really the overall thickness of the top (which I calculate by ‘feel’ depending on the type of timber) combined with the amount of material I remove from the braces that results in tops of differing stiffness.

I count myself among those makers who listen closely to the ‘tap tone’, assuming that a bell-like ring will translate into a more musical instrument when finished. It’s not an exact science, but it’s a useful way of reading the top.

The trouble is, if we makers determine the ‘perfect’ guitar must be one that follows a regimented set of scientific principles and measurements, then we might obtain some consistency across the instruments we build – but at what cost?

I have played some badly made guitars that sounded incredible; they just had something special about them. To build guitars in a purely technical way is to completely overlook the excitement of playing a guitar that sounds, looks and feels truly unique. After all, beauty is in the ear of the beholder.